Questions?

Why buy a collaborative robot?

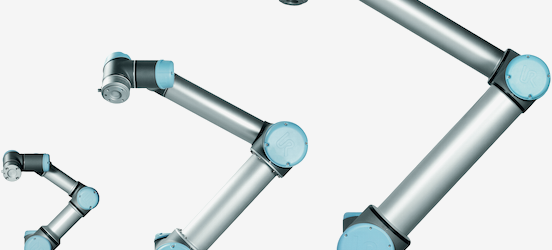

Universal Robots has reinvented industrial robotics with lightweight and flexible robot arms. With established service and support in more than 40 countries worldwide, the Danish-designed robots automate tasks across the entire industrial sector. Return on investment is rapid, making an investment in UR robots affordable.

- ISO Compliant for Collaborative Robots

- 3, 5 and 10 Kilogram Payloads Available

- Simple to Use and Works Right Alongside Employees

- Precision Handling and Performance

- Light-weight and Flexible Robot Arms

- Programming Through Intuitive Touch Screen

- Faster, Easier to Implement and More Affordable

control and teach pendant

Collaborative robots

Universal Robots has revolutionised the robotic market with their innovative robotic arms UR5 & UR10, which can handle payloads of up to 5 and 10 kilos respectively.

Their UR3 model (released in 2015) can handle payloads up to 3 kilos and delivers high-precision accuracy for smaller production environments.

They are the flexible, light weight and user friendly 6 axis industrial robots that solve a lot of problems inherent to traditional industrial robots.

They are developed specially for small to large enterprises, who need robotic automation but without the big safety issues, complexity, floor-space, expensive installation and lack of flexibility.

Their significantly lower implementation cost and the ability to be easily re-deployed for another task is flexible and effective automation that can provide fast return on investments.

The robots are easy to move around and do not require sturdy bases due to their light weight structure.

They also run on 110v. The end of arm tool may require other power supply (air , electric).

The robots are delivered with everything that is required for programming:

This includes the controller box, touchscreen and software.

The unique graphic user interface on the touchscreen makes programming easy (through ‘teach’)and the requirement for robot experts redundant.

The built-in PLC has enough inputs and outputs (digital and analog) to suit most situations.

The built-in Ethernet based interface allows to add more devices (field I/O, touch screens, vision systems).

Ragot CAD/CAM Services, a division of Maritime CAD/CAM and cobot Ltd. , is a certified system integrator:

General brochure: